Category: General

Volvo ES90 electric sedan gets 800V charging, sustainable materials

- Upcoming ES90 will get 800-volt architecture, 350-kw fast-charging

- Smaller battery than EX90 electric SUV, yet a longer range

- Recycled plastics, certified wood, and battery passport all part of eco credentials

The Volvo ES90 electric sedan will be the first of the Swedish automaker’s electric vehicles with an 800-volt electrical architecture, and will continue Volvo’s emphasis on sustainable materials.

First teased last fall, the ES90 is due to be revealed Mar. 5, but Volvo is releasing some details to build up hype ahead of that. On Wednesday, the automaker sent out a press release focused on charging and sustainability aspects of the new sedan.

On the charging side, Volvo confirmed an 800-volt electrical architecture that will allow European-spec versions of the ES90 to charge at up to 350 kw and recover up to 186 miles of range in 10 minutes of charging at that power level.

The automaker also expects the time for a 20-minute 10-80% charge, compared to 30 minutes for the EX90 SUV, with 400-volt hardware. But it hasn’t yet said whether the ES90 will also offer the bidirectional charging capability that’s been promised for the EX90.

2025 Volvo EX90

Volvo is aiming for 435 miles of range, as measured on the European WLTP testing cycle. That’s based on a dual-motor powertrain and 106-kwh battery pack, although Volvo didn’t specify whether the battery capacity was usable or gross. For reference, the EX90’s pack is 111 kwh gross, with 107 kwh usable. And it’s worth remembering that WLTP numbers don’t directly translate to the U.S. EPA cycle, although the ES90 should still manage well over 300 miles in EPA testing.

Volvo also claims that it will keep the overall carbon footprint of the ES90 with meaningful use of sustainable materials. The automaker claims 29% of the aluminum, 18% of the steel, and 16% of the plastic polymers used in the car will be recycled material, while all wood trim will be certified by the Forest Stewardship Council (FSC) as sustainably harvested.

The ES90 will also have a blockchain-based “battery passport” that tracks the sourcing of raw materials—including cobalt, graphite, lithium, and nickel—as well as the overall carbon footprint of the battery, according to Volvo.

Volvo ES90 teased ahead of debut on March 5, 2025

While still based on the SPA2 architecture used by the EX90, the ES90 is shaping up to be a true evolution of that platform, rather than just the same components packaged in a new body style. In addition to its 800-volt electrical architecture, the ES90 will debut more powerful chips for Volvo’s Superset tech stack. Those chips will be retrofitted to EX90 models as well, under a timeline and details yet to be confirmed.

The ES90 is one of 10 new and updated models Volvo plans to introduce over the next two years. In addition to more EVs, some of them will be longer-range plug-in hybrids as Volvo backs away from a previous goal of going all-electric by 2030.

Lucid CEO Peter Rawlinson has stepped aside after Gravity launch

- Rawlinson becomes advisor as Lucid delivers Gravity, pivots to more affordable EVs

- CTO of Lucid and parent Atieva since 2013, led efficiency-and-performance push

- Oversaw Lucid Air and Gravity, Tesla Model S

Peter Rawlinson is no longer the top executive at California’s Lucid Motors.

In a press release, Lucid said that Rawlinson “has stepped aside from his prior roles,” and will transition to a role as senior technical advisor to the chairman of the board at Lucid, while COO Marc Winterhoff has been made interim CEO.

Rawlinson was elevated to the role of CEO at Lucid in 2019, but it’s the chief technical officer (CTO) role that he doubly held that’s been especially important. As the engineering wizard behind a lot of what has propelled the company to its technological preeminence, Rawlinson has positioned Lucid to grow as a propulsion-efficiency juggernaut. It’s shown how it could make powerful EVs providing more range—even versus rival Tesla. As such, Lucid was the first automaker to crack 500 miles of EPA-rated range without an absurdly large battery pack.

Lucid CEO Peter Rawlinson – Arizona plant commissioning

“Now that we have successfully launched the Lucid Gravity, I have decided it is finally the right time for me to step aside from my roles at Lucid,” said Rawlinson, in the release. “I am incredibly proud of the accomplishments the Lucid team have achieved together through my tenure of these past twelve years.”

It has indeed been that long. Rawlinson joined Lucid’s parent, Atieva, as chief technology officer in 2013. Rawlinson and design chief Derek Jenkins first presented to a small group, including yours truly, a concept version of the Air in 2016, when Lucid became the automotive brand of Atieva.

Lucid almost didn’t make it—and might not have without Rawlinson’s perseverance. Ford considered buying Lucid in 2018, then took a pass. Finally in April 2019, with the completion of an initial $1 billion investment from the Saudi Arabian Public Investment Fund (PIF), things got real and development accelerated.

Amid Lucid’s cash-strapped starvation era, from 2017 well into 2019, Rawlinson kept a core engineering team and revisited some of the key tech in the Lucid Air—what he called the core competence of the company. That led to the breakthroughs like the 900+ volt tech and Lucid’s own permanent-magnet motor design it uses today. In the meantime Lucid had started providing Formula E battery packs for the entire racing series, which added to the company’s knowledge base.

The company has “initiated a search to identify Lucid’s next Chief Executive Officer,” with support from an executive search firm, according to the release. “The new CEO will help Lucid execute its strategy and prepare for the next chapter,” it stated.

Peter Rawlinson

Rawlinson has held positions at Jaguar and Lotus, among other companies, but Green Car Reports first came to know Rawlinson when he was Tesla’s chief engineer for the Model S, responsible for its design and production. Back in 2011, when he was in that role, Rawlinson told GCR that he was particularly proud of the Model S battery pack and how it fit electrically and mechanically within that trailblazer, which would go on to win all sorts of awards.

The Lucid CEO has managed to hire top-tier talent at the automaker, including Tesla’s former manufacturing chief and other top executives from VW, BMW, and Apple, and hold on to them in a way Tesla hasn’t. He kept Lucid’s braintrust in the California’s Bay Area, but it opened its Casa Grande, Arizona, factory in 2021.

Lucid midsize SUV teaser

The Lucid Air has been Green Car Reports’ Best Car To Buy, and even though it’s a very large car, the Air Pure stands as America’s most efficient EV. It’s now delivering the Lucid Gravity SUV and hopes to more than double its vehicle production this year as a result of having the model in the mix. And three affordable EVs, built off a new midsize platform and with an even lower-cost Atlas drive unit spearheaded by Rawlinson as key to getting to further economies of scale, are due within a couple years.

For now, Rawlinson and that tech preeminence remain Lucid’s strength; he’s suggested that it would take years for the competition to catch up with Lucid’s efficiency edge, and he may be proven right.

2025 Mercedes-Benz EQB re-ups electric GLB-Class formula

The 2025 Mercedes-Benz EQB electric SUV carries over mostly unchanged, retaining its status as the entry-level EV in Mercedes’s U.S. lineup and the only one sharing a platform with an internal-combustion vehicle.

The EQB is a fully electric derivative of the boxy Mercedes-Benz GLB-Class, with smoother styling details that soothe the GLB’s coefficient of drag to 0.28 but sport essentially the same packaging. For 2025 it adds a better-equipped Exclusive grade, including a surround-view camera system, Burmester surround sound with Dolby Atmos, and heated front seats.

Also new is a Design Package with different exterior and interior styling cues, and Manufaktur Mountain Grey Magno paint. Customers also have new 18- and 20-inch wheel options.

2025 Mercedes-Benz EQB-Class (EQB 350)

Powertrain options include a single motor sending 188 hp and 284 lb-ft of torque to the front wheels in the EQB 250+ and dual-motor all-wheel drive in the EQB 300 4Matic and EQB 350 4Matic. The AWD models have permanent-magnet motors in front, induction in the back. While the EQB 350 4Matic is software-enabled for 288 hp and 384 lb-ft, the EQB 300 4Matic is limited to 225 hp and 288 lb-ft.

All versions have a 70.5-kwh battery pack, which provides 251 miles of EPA range in the EQB 250+. That drops to 205 miles for the EQB 300 4Matic, but rebounds slightly to 207 miles with the EQB 350 4Matic.

Introduced for the 2022 model year, the EQB received a refresh for 2024 that included Plug & Charge compatibility, allowing owners to simply plug in and be automatically billed later.

2025 Mercedes-Benz EQB-Class (EQB 350)

Even with a peak 100-kw DC fast-charge rate, the battery allows a 10-80% charge in 31 minutes. The 9.6-kw onboard charger in U.S. models makes a full overnight charge well within reach for the most common Level 2 setup, that being a 50-amp circuit and 40-amp charging.

Pricing remains unchanged, meaning the base 2025 Mercedes-Benz EQB 250+ still starts at $54,200 including the $1,150 destination. The EQB 300 4Matic and EQB 350 4Matic cost $58,150 and $61,800, respectively.

The EQB is likely to be replaced soon with a new model based on the Mercedes Modular Architecture (MMA) first arriving in the 2026 CLA. Like the CLA, the same model could be offered with both all-electric and mild-hybrid powertrains as Mercedes moves away from dedicated electric models.

Here’s how in-wheel motors could cut EV cost, boost range 20%

- In-wheel motor maker Elaphe doesn’t see issues with durability or unsprung mass

- “Vehicle-level” integration of tech could bring 20% cheaper vehicles, 20% efficiency boost

- Elaphe is targeting 95% efficiency on a battery-to-wheel basis by 2030

If you took a quick look at the display stand for Slovenia’s Elaphe Propulsion Technologies at CES 2025 last month, you might have walked away with the message that the supplier of in-wheel motors has moved on from Aptera, Lightyear, and Lordstown and is pitching its tech to cars that are fast, exotic, and expensive.

That much is true—in the short term. Long-term, Elaphe has a grander global vision than just fitting into the performance picture.

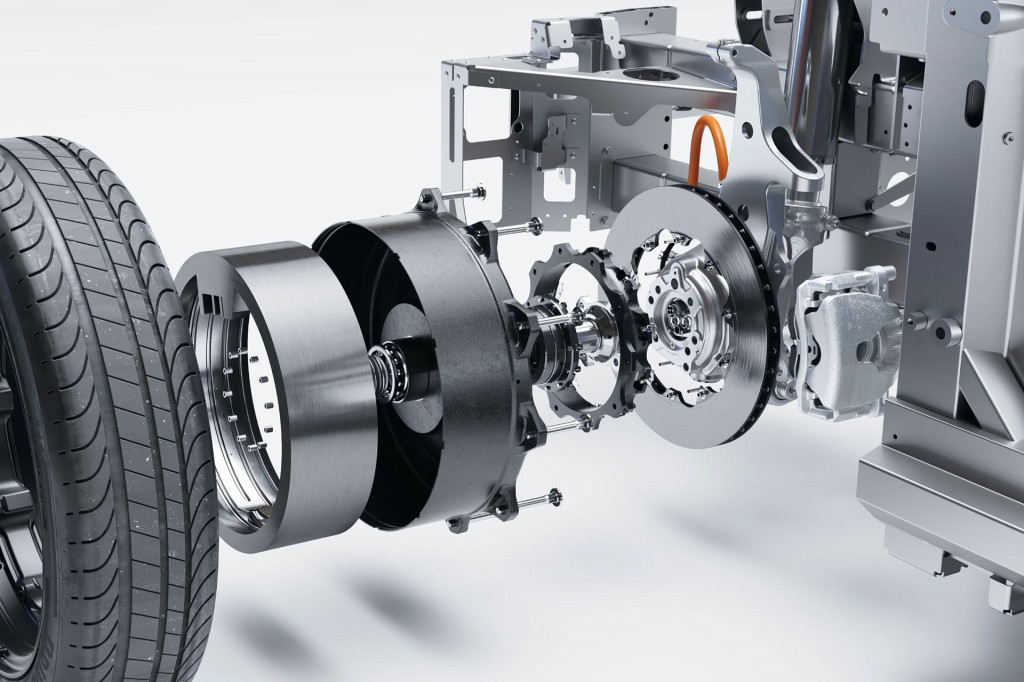

In the meantime, it sees performance vehicles as the perfect venue for showing tech-savvy car buyers what in-wheel motors can do. At CES, Elaphe revealed a revised in-wheel motor design, called Sonic 1, that’s compatible with larger, track-ready brakes and high-performance vehicles.

In a rear-engine, rear-wheel-drive model, for instance, it could deliver “something extra,” as brand and marketing architect Iztok Franko put it, at the front wheels without redoing the architecture of the vehicle—as part of a hybrid performance upgrade.

Elaphe Sonic 1 in-wheel motor for performance cars. – CES 2025

The Sonic 1 motors themselves, which it teases are likely to arrive in a production vehicle in 2026, can make up to 268 hp and 737 lb-ft each in their default form—designed to fit a 21-inch front wheel, as shown. And to take it to a scorching extreme, they’re being developed to fit up to 24-inch wheels, as Elaphe and its stand partner Italdesign teased in an updated Quintessenza supertruck concept, offering a hypothetical combined max of 1,600 kw (nearly 2,150 hp).

“So now we remove the obstacle of reengineering the whole vehicle, it’s easy to integrate, and you can upgrade the performance and upgrade the control of the car,” said Franko.

Italdesign Quintessenza concept

In-wheel tech promises simplicity, efficiency

If you compare it to an e-axle with an inboard motor, there are no additional mechanical losses, because it’s only one rotating part per motor. There are no additional bearings, gears, or added constant velocity joints, either.

It’s a good start to thinking about what in-wheel tech can do, and why it’s been popular for some vehicle types, like very large trucks and buses. But it’s only scratching the surface for what Elaphe and the few other companies see as a bright future applying the tech to passenger vehicles.

Green Car Reports caught up with Elaphe chief technology officer Gorazd Gotovac at CES about how its technology is evolving and found a company that sees in-wheel tech as a key part in the long-term future of the car.

Gotovac emphasized to Green Car Reports that over many years and iterations, the company has worked to fine-tune the design through inverter control and management of second-order effects in the physics of the magnetic field. Partly through that it’s achieved a 10% efficiency boost versus the previous generation of its motors, from fourth to its current fifth generation.

Elaphe in-wheel motor for Lightyear 0

By the time Elaphe gets to production in high volume, which it sees as around 2030, it’s targeting a 95% efficiency, on a battery-to-wheel basis, based on highway driving.

Its design uses permanent magnets, but Gotovac says that the company has already confirmed that by 2030 it will be able to bypass the use of heavy rare-earth materials, keeping to lighter rare-earths instead and reducing the environmental footprint.

“We believe that once in-wheel motors are adopted there will also be versions without permanent magnets on the low end of the market,” he added. “But it will bring some weight penalty.”

Unsprung mass isn’t such a big deal

In-wheel motors increase the amount of unsprung mass (all the mass not supported by the suspension), which auto engineers and insiders routinely claim makes ride and handling much harder to tune and complicates safety.

It’s simply not as significant of an issue as some vehicle engineers paint it to be, according to CTO Gotovac. That’s because wheels and tires, in combination, are quite heavy; add an in-wheel motor and you’re not at all doubling or tripling the weight, he explained to Green Car Reports. You’re boosting it by about 30% when figuring in the brakes and all the ancillary pieces. Factor in items that are redundant for in-wheel motors and the gain in unsprung mass can be as little as 35 pounds per wheel versus an inboard motor setup.

And adding in-wheel motors at the front wheels is an easier way to add hybrid propulsion while maintaining safety, argued Gotovac. “If you have a car which has been engineered and crash-tested and you want to hybridize it, you have to redo all the crash-testing,” he said. “But if you put in-wheel motors in, you don’t have to redo all the crash-testing, because actually the structure in front, it will be the same…and if you’ve done the engineering right the wheels are just going to hold onto the rest of the structure.”

Elaphe’s units are designed to survive minor collisions, and it means that the body doesn’t need a crash structure designed around incompressible powertrain pieces.

Lordstown Endurance

Durability work already done on in-wheel motors?

What makes in-wheel motors fundamentally different than existing inboard motors is that the motor’s rotor spins directly with the wheel and its stator acts as the hub. Because of this, they’re subject to higher levels of vibration and road shocks, but Elaphe’s Gotovac insists that durability is no longer a concern. In recent years it has pushed its full validation cycle for the vehicle lifetime of its motors out to 300,000 miles, from the previous 150,000 miles.

Lordstown Motors would have provided that real-world evidence of durability for Elaphe, in its Ohio-built Lordstown Endurance electric pickup, using U.S.-built motors from the Slovenian company—if it weren’t for Lordstown’s demise in June 2023.

As Gotovac emphasized, the design of the motor that Elaphe still follows was fully validated in the Endurance, but it was a different application as Elaphe itself didn’t have anything to do with the inverters, which allow a finer level of motor control. In a drive of the Lordstown Endurance, Green Car Reports didn’t have any issue with motor response, ride, or handling of the electric truck.

2023 Lordstown Endurance

One of Ford’s top EV executives, Darren Palmer, told Green Car Reports in 2021 that it nixed in-wheel motors as a possibility in the F-150 Lightning electric truck over concerns about durability. And Aptera dropped in-wheel motors for its production-bound three-wheeler in what appeared to be an issue not with any of those concerns but with cost.

At present, there are some, but relatively few, examples of mainstream models that offer these motor types. China’s Dongfeng, in 2023, claimed to be building the world’s first passenger car with in-wheel motors—powering the rear wheels in that case, supplied by Protean Electric.

In the meantime, in-wheel motors continue to look like the future, albeit a future without any significant present-day commitment—and plenty of false starts. Perhaps backing up Elaphe’s claims that they’re the best solution for the future, Hyundai and Toyota have continued to develop their own in-wheel motors, or at least remain involved in their development.

Lightyear with Elaphe motors

In-wheel motors remain mass-market-bound

As Elaphe’s Gotovac explained to Green Car Reports at CES, the company sees niche high-performance applications like Sonic 1 as an important step in getting the word out about in-wheel motor technology and how it can perform to extremes. But it has bigger-picture ambitions at the affordable end of the market.

This is the fifth generation of Elaphe’s motors and it’s been simultaneously working toward higher power density and better performance while also keeping an eye on how the tech can truly be applied to the mass market.

Gotovac said that while selling automakers on the idea of in-wheel motors for mass-market EVs has proven challenging, the technology can potentially pay much greater dividends.

“We are able to develop this power-dense design that we have into something that is cost-effective for a car that doesn’t have to be as powerful,” he explained. “If you’re using less material to get more power out of it, and if you’re not using exotic materials, then your potential for cost is better than the previous generation.”

Aptera with Elaphe motors

In-wheel motor potential: Ride, handling, identity

Elaphe’s Sonic 1 motor system is designed to use an inverter from its official partner McLaren Applied Technologies, with software developed with that firm—and the key to some of those special control strategies is the software.

But Elaphe emphasizes that the potential for in-wheel motor tech rests on much more than power delivery. Once you have it at each wheel, all sorts of opportunities arise for the motors to take an active role in: ride, handling, stability control, and even communication to the driver.

Aptera with Elaphe motors

Fundamentally, one of the key advantages of Elaphe’s in-wheel motor technology amounts to this, Gotovac explained: It’s capable of blipping torque delivery—up to its peak torque delivery—almost instantaneously, more precisely than an automaker could with brakes, and in a more extreme way than automakers would ever dare with an inboard motor because of driveshafts and CV joints.

Allowing roll control to be handled by the in-wheel motor system, Gotovac says, would allow automakers to eliminate physical roll bars and their constraints. If you have a motor at each corner, coordinated by a central computer, it’s like having “just one brake in the middle…you feel very safe when you get on ice,” Gotovac explained, or the motors can squeeze at varying levels with just the right timing so as to provide roll control.

Elaphe is currently working toward a very quick 10-kHz modulation cycle and a reaction time of just 4 milliseconds for full torque delivery of its motors. It takes the quickest inboard motor systems 20 times as long to respond, Gotovac claimed, and even then they won’t be able to provide close to full torque. “So that means we really can control with very high bandwidth, a lot of force,” he said, inserting with a smirk: “So we can get very interesting effects.”

Those effects can be quite subtle, he says—like engineering some vibration or tonality back into the driving experience. “We can generate vibration so that you can get a feeling in the car which is engineered but still authentic,” he said, or have the motors generate safety alerts, play songs, or emulate combustion engines—serving a purpose not unlike what Stellantis has engineered for the Dodge Charger Daytona EV.

All of those are things you can’t do with an inboard-motor EV because there are too many other factors with the driveshafts and suspension, and concerns over durability or the harmonics of the gear system.

2024 Dodge Charger Daytona

The future: EVs built on platforms for in-wheel motors

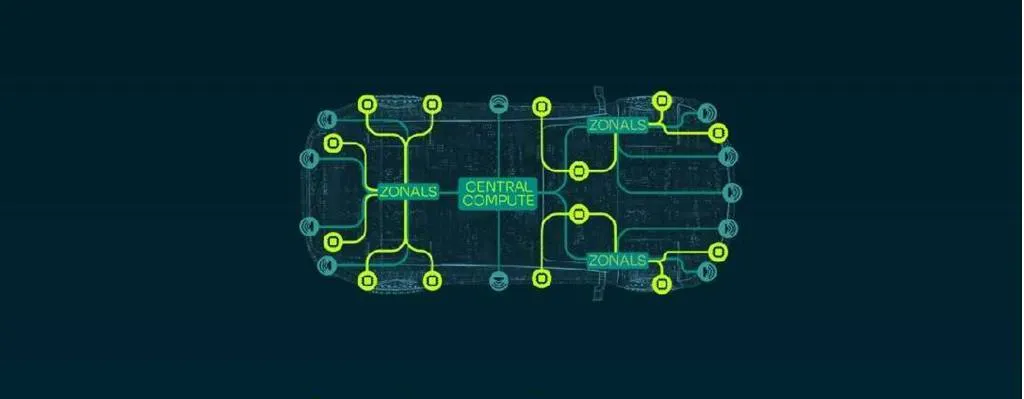

None of this tech will be fully realized, Gotovac admits, until we get a new kind of EV, conceived from the start for in-wheel motors. Enabling their potential is a “vehicle-level issue,” he says, and in-wheel motors will only make the vehicle much more efficient if it’s engineered from the ground up for the tech.

If automakers are up for playing this long game with Elaphe, it believes it can lower overall vehicle cost by 20% and boost range and efficiency by 20%—including whole-vehicle design, aerodynamics, chassis controls, and the weight of the car. “That’s where the big potential lies,” Gotovac said.

No major automaker has signed up yet. And what exactly keeps automakers from committing to in-wheel motors on big, mass-market, affordable EV projects sounds like a classic chicken-or-egg dilemma.

Rivian and Volkswagen Group electrical architecture and software stack

Getting to the 20% efficiency boost requires a big investment and commitment that goes beyond the supplier, lamented Gotovac, including an electrical architecture intended to accommodate it. “On the component level we can demonstrate a little bit of efficiency improvement, but not enough for them to make a $5 billion investment,” he added, summing up the predicament.

Gotovac asked rhetorically: “What is the step in between that gets them to believe in this system, so that they engineer that new platform? That’s the thing…”

It’s what drew my attention back to the Sonic 1 motor unit on the pedestal, ready in the meantime to create an Italian exotic that, perhaps, the tech-savvy will recognize for all its firsts.

Mercedes EQS aims for 621-mile range, tests solid-state battery

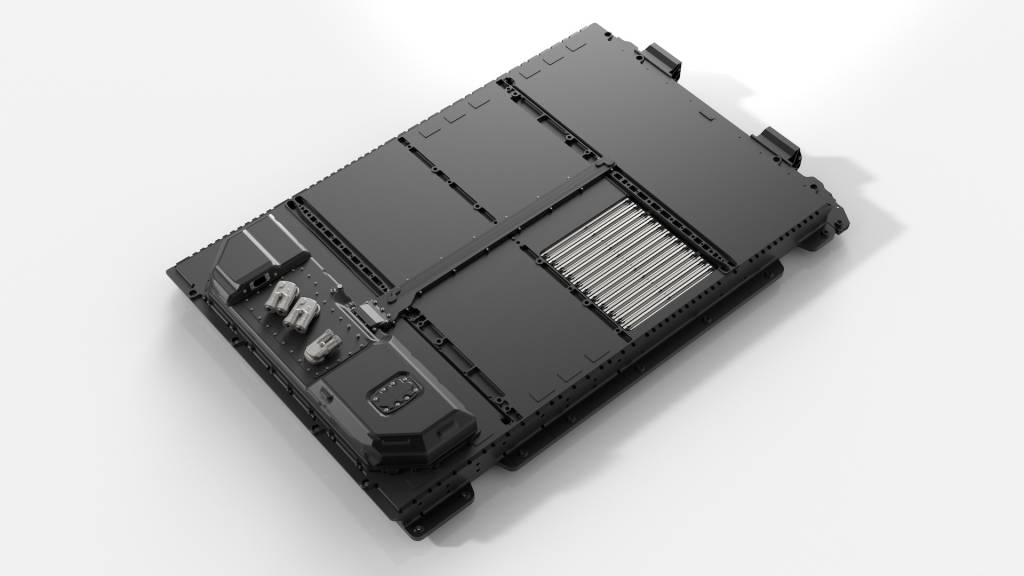

Mercedes-Benz on Monday announced the start of real-world testing of prototype solid-state battery cells from the U.S. firm Factorial.

These cells were installed in a Mercedes-Benz EQS sedan in late 2024, and the car has been used in laboratory tests since then, according to a Mercedes press release. The automaker now claims the EQS is ready for road-testing—and that it could achieve up to 621 miles of range (1,000 km, on an unconfirmed drive cycle) with solid-state cells.

Mercedes-Benz EQS solid-state battery prototype

That range is possible mainly due to the solid-state cells’ increased energy density. Mercedes claims these cells allow for 25% more energy (and range) for the same weight and dimensions of the standard EQS battery pack. Passive battery cooling, such as what was used in the Mercedes EQXX engineering concept, will also help lower weight and increase efficiency.

Developed with input from Mercedes’ Formula 1 powertrain unit, the EQS test vehicle’s battery pack uses a new floating cell carrier, with pneumatic actuators that compensate for expansion and contraction of the cells as they charge and discharge, respectively.

Mercedes-Benz EQS solid-state battery prototype

The partnership between Mercedes and Factorial goes back to 2021. Factorial began providing test cells to Mercedes (as well as Stellantis) in 2022, and in 2024 appeared confident that its cells could boost Mercedes EV range by up to 80%. The Massachusetts-based battery firm has also opened what it claims is the largest U.S. EV solid-state battery plant yet in a Boston suburb. But that plant—with which aims Factorial aims to eventually produce up to 200 gigawatt-hours of batteries annually—is still small compared to conventional battery plants.

Mercedes will continue its testing in the laboratory and on the road over the next few months, but it may lead to a commitment to use solid-state cells in production vehicles. And if they are commercialized, a new micro-converter also being developed by the automaker plus some extra cooling-system innovation might allow them to be mixed with other cell types in the same EV battery pack.

Mini Cooper EV production in UK delayed

Mini is delaying electric vehicle production at its U.K. plant, which could further delay U.S. sales of both a redesigned electric Cooper hatchback and the Aceman, a new nameplate being sold only as an EV.

Both models are currently built in China and were due to be added at Mini’s Oxford, England, plant next year. But Autocar reported Friday the U.K.-made Mini EVs are delayed “for an unspecified period of time,” citing Mini parent BMW.

“Given the multiple uncertainties facing the automotive industry, the BMW Group is currently reviewing the timing for reintroducing battery-electric Mini production in Oxford,” a BMW spokesperson told Autocar.

2025 Mini Cooper electric hatch

Mini has already spent more than 600 million British pounds (approximately $758 million at current exchange rates) to ready the Oxford assembly plant and a nearby body plant in Swindon for EV production. The automaker confirmed to Autocar that it’s returning a related government grant.

Mini confirmed last November that a decision on whether to sell these electric models in the U.S. was being delayed. That left the door open for one or both models to reach the U.S. eventually, but that’s likely dependent on U.K. production. China-produced versions of the Mini Cooper and Aceman are likely non-starters for the U.S. due to steep tariffs. Mini did start taking orders for the Countryman SE ALL4 electric crossover last year.

Already on sale in Europe, the current-generation Mini Cooper EV was unveiled alongside the Countryman SE ALL4 at the 2023 Munich auto show, promising more range than the 114 EPA miles of the outgoing Mini Cooper SE. Gasoline versions of the current-generation Cooper are being sold in the U.S. as 2025 models.

2025 Mini Aceman

The Aceman crossover, sized between Cooper and Countryman, was unveiled in early 2024. That’s smaller than the Hyundai Kona Electric or Volvo EX30, which has made it a long shot for the U.S. all along.

Mini aims to go all-electric by 2030, and it has also shown sportier John Cooper Works (JCW) versions of some of its recent EVs. But a delay in U.K. production will likely further push back the introduction of them to the U.S.

Rolls-Royce Spectre brings Black Badge into electric era

In recent years, Rolls-Royce has launched a series of Black Badge models aimed at updating the stalwart luxury brand’s image with a more youthful and sporty demeanor and a darker color palette. Now the first electric Rolls-Royce—the Spectre coupe—is getting the Black Badge treatment.

Rolls claims it’s the most powerful production car it’s ever sold—gasoline or electric. That’s thanks to a retuned version of the Spectre’s dual-motor powertrain, which is now rated at 659 hp and 792 lb-ft of torque. Those are increases of 75 hp and 128 lb-ft over the standard Spectre.

Full power is unlocked via Infinity Mode, which also sharpens accelerator response, but Rolls-Royce also created a Spirited Mode launch mode that allows the Spectre Black Badge to accelerate from 0-60 mph in 4.1 seconds, according to the automaker.

Rolls-Royce Spectre Black Badge

Spirited Mode is activated by fully depressing the accelerator and brake pedals, then releasing the brake, making it somewhat like the launch modes available in other high-power EVs. Such a feature might seem a bit out of character for the stately Rolls brand, but the automaker claims that a review of anonymized data voluntary provided by current Spectre owners showed a desire for such a feature, impart because drivers tended to use max power mainly in short bursts.

Other mechanical changes include retuned steering with a heavier feel, and suspension that aims for better body control and reduced squat under acceleration. It’s unclear how these changes will affect EPA range, which currently sits at 291 miles. That’s achieved with a 102-kwh battery pack, making the Spectre surprisingly efficient for a gilded luxury car—making 260 EPA-rated miles out of 102 kwh.

The Black Badge treatment also brings darkened chrome trim and 23-inch wheels on the outside, which in the press photos is matched by brooding Vapour Violet paint. Customers will have access to the typical large catalog of paint options, though, and even multiple colors for the car’s illuminated grille.

Rolls-Royce Spectre Black Badge

Inside, an elaborate interior motif consisting of 5,500 individual lighting elements is sprinkled across the dashboard and door panels, set against a piano black backdrop to give the impression of a night sky. It’s paired with what Rolls-Royce calls Technical Fibre, comprised of woven carbon fiber and metal over a wood base.

Such decadence is currently rare among EVs, but obligatory for a Rolls-Royce. The Spectre likely won’t be the ultra-luxury brand’s only electric model for long, as Rolls is also reportedly planning an electric SUV and sedan.

Feds purge EVs, chargers: Does Musk still believe EVs cost less to run?

- Report suggests GSA may be forced to pull the plug on thousands of EVs and chargers

- GSA’s biggest fleets are USPS, Dept. of Defense; 20% of its 2024 light-vehicle orders were EVs

- Could affect chargers at national parks, VA hospitals, other venues

The U.S. General Services Administration (GSA), which manages all federal government buildings and has been nicknamed by some as the largest landlord in the world, is reportedly planning to shut down its EV chargers and offload some or all of its EVs.

The move would take about 8,000 charging connectors and thousands of EVs out of service, according to a report from The Verge, citing a GSA email and a source familiar with the plans.

If so, it might amount to an exceptionally strange juxtaposition for Elon Musk. The Tesla CEO has spent years admirably facing down Tesla short-sellers on the viability of EVs and selling the public on how EVs cost less to own and use over the long run—even claiming, perhaps optimistically, at various points that Tesla’s EVs would be appreciating assets. Musk is now managing the Department of Government Efficiency (DOGE), which according to the Trump administration seeks “to modernize federal technology and software to maximize governmental efficiency and productivity.”

If running an EV and keeping electricity flowing to its Level 2 charger isn’t the technology that maximizes cost savings for the fleet over the long run, as Musk has argued for years, the Tesla CEO might need to update some of its core selling points for EVs—or have a conversation with shareholders.

The news of the charger shutdown and EV purge was first reported by Colorado Public Radio on Thursday, which reported that chargers at the Denver Federal Center were due to be shut down. The Verge then reported Friday that it had obtained the GSA email telling federal workers to begin the process of shutting down all EV chargers overseen by the agency, which is reportedly due to be formally announced internally next week.

Volkswagen, Oak Ridge National Laboratory, and UT Knoxville test wireless charging

The GSA currently operates or hosts various Level 2 AC chargers across the country, totaling about 8,000 connectors. They’re mostly there to charge government-owned EVs, but they also charge personal vehicles of federal employees, according to The Verge. Examples of charger locations seen by Green Car Reports as under GSA control that might affect public accessibility might include publicly accessible locations at national parks and VA hospitals.

Highway fast-charging infrastructure already frozen

If true, it will be the second significant impact by the Trump administration on EV chargers that were essentially already paid for. It froze EV charger funding earlier this month, pending new rules not yet released, something automakers have already rallied against. California plans to move ahead with its own EV charger buildout despite the funding freeze; it’s also promised to offer purchase incentives for most EVs (likely not including Teslas), equivalent to the current federal tax credit, should the administration eliminate that.

“As GSA has worked to align with the current administration, we have received direction that all GSA owned charging stations are not mission critical,” the email reads.

There’s nothing to directly indicate that the decision to shut down chargers comes from Tesla CEO Elon Musk. But the term “not mission critical” echoes language often used by Musk, who has been arbitrarily cutting federal spending and jobs in his role as an advisor to the Trump Administration. And, if this is overseen by Musk, it directly conflicts with the CEO’s longtime efforts suggesting that Teslas would make good public-service vehicles with lower operating costs.

Tesla CEO Elon Musk suggesting Tesla EVs cost less for patrols

Some regional federal offices have already been instructed to take their chargers offline, according to The Verge, which adds that the GSA is looking to cancel current network contracts that keep chargers operational. Once those contracts are canceled, chargers will be “turned off at the breaker,” the email reads.

The federal fleet overseen by the GSA currently includes approximately 650,000 vehicles, more than half of which were due to be replaced with EVs under a Biden administration plan. Although a fleet summary hub page has been removed, a November 2024 release from the GSA notes that it’s ordered a cumulative 82,000 EVs and installed more than 10,500 individual charging ports, with an additional 52,535 charge ports in progress. It also reported that EVs made up 20% of its light-duty vehicle orders in 2024.

2022 Ford F-150 Lightning

The report, citing the same source with knowledge of the plan, notes that GSA-controlled facilities will stop using EVs and start offloading them, although it’s not clear whether these will be sold or stored.

Of course, chargers at facilities are essential for keeping government EVs in service. “You can’t have an electric vehicle if you can’t plug it in,” said Mark Dowd, who was the Biden administration’s director of zero emission vehicles and on the White House Council on Environmental Quality, in a 2023 podcast from the administration.

Independent of any vehicle spending, the previous administration also allocated $975 million to the GSA to upgrade federal buildings with “emerging and sustainable technologies”—including EV charging—so it’s unclear how much of that outlay it would be abandoning in doing so.

USPS Next Generation Delivery Vehicles (NGDV) – Oshkosh Defense

Fraught USPS EV order in question, again?

U.S. Postal Service vehicles comprise more than a third of the GSA fleet, and non-tactical Department of Defense vehicles make up another third. All the other federal agencies make up the other third.

Of course, this begs the question of whether the United States Postal Service (USPS) will take delivery of as many EVs as anticipated, after a debacle that led to a plan to purchase mainly gasoline vehicles. The federal government currently has tens of thousands of EVs in use, and it planned to replace more than half of its approximately 650,000 vehicles with EVs.

GSA either helps buy vehicles for agencies or leases them to agencies, depending on the situation. Under a Biden executive order, GSA was transitioning to all-electric vehicle purchases by 2027. GSA replaces a small percentage of its vehicles annually; vehicles haven’t been pre-emptively replaced with EVs, rather as gasoline models reach the end of their service life. Examples include a push to switch National Park Service vehicles from gasoline F-150 trucks to Ford F-150 Lightning models on an ongoing basis.

GSA keeps vehicles in use a long time, according to federal data, and in many cases well into high mileage, which seems like an ideal use case for EVs. According to its own current standards, the minimum life cycle for replacement of electric trucks, for instance, is seven years or 90,000 miles. Many vehicles in the GSA fleet are much older.

Tesla website promoting savings over gasoline vehicles – Feb. 2025

Musk has spent much bandwidth on EVs as smart money

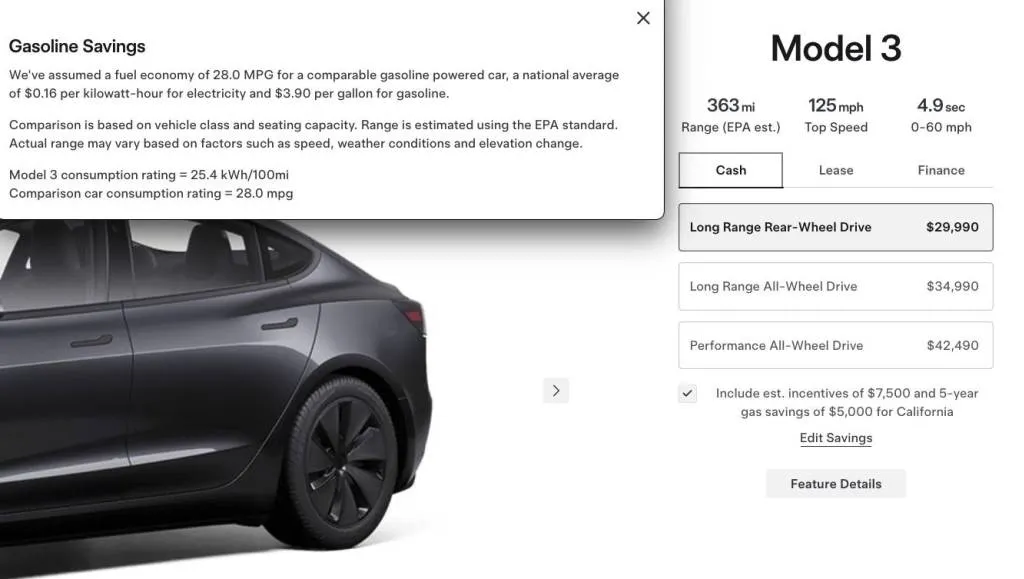

As Tesla CEO Elon Musk has repeatedly emphasized over a span of more than a decade, and as Tesla’s very own site has aggressively pushed this as a built-in part of its pricing, EVs cost less to run—not just to fuel, but to own and maintain. According to Tesla the Model 3, for instance, has a five-year gas savings of $5,000 based on 10,000 miles a year or $7,500 based on 15,000 miles a year (with Los Angeles as the location). Longer maintenance intervals on EVs, including items like brake pads and fluids, mean preventative maintenance costs are far lower.

If Musk is at all behind this, it leads to a bigger question: If the chief cost-cutter and efficiency master doesn’t actually believe that EVs are cheaper and more efficient for the government to be running daily—or can’t convince President Trump that they are—will Tesla continue to sell its own vehicles on that premise?

–with reporting by Stephen Edelstein and Bengt Halvorson

2026 Polestar 3 EV gets a more powerful brain; so will 2025 models

The Polestar 3 electric SUV will get an upgraded chipset for its second model year, the automaker confirmed Thursday in a press release.

Due to arrive in showrooms later in the 2025 calendar year, the 2026 Polestar 3 is the first of the brand’s EVs to receive the Nvidia Drive AGX Orin processor, a more powerful successor to the Drive AGX Xavier processor the SUV launched with.

2026 Polestar 3 charging

In addition to being installed in newly built vehicles, the more powerful processor will be offered as a free upgrade to existing Polestar 3 owners. Parent brand Volvo earlier this week confirmed it’s doing the same thing for owners of the EX90 electric SUV, which shares the SPA2 architecture with the Polestar 3.

Overall, it’s unusual for an automaker to update hardware post-sale rather than just software.

Volvo has said the added computing power of the Drive AGX Orin, which will also be used in that brand’s upcoming ES90 electric sedan, will support AI-based features, more sophisticated safety tech, an array of onboard sensors, and a more efficient battery management system. That will likely be the case for the Polestar 3 and any future Polestar models that use this chipset as well.

2026 Polestar 3 Plug & Charge

The 2025 Polestar 3 is built in Charleston, South Carolina, and it arrived as a sportier, two-row counterpart to the three-row Volvo EX90 with which it shares a platform. All versions have a 111-kwh battery pack, with up to 350 miles of range in base single-motor rear-wheel-drive form.

Polestar hasn’t yet given a timeline for when it will update existing 2025 models, but it says it will contact customers when the new chips are available. Installation will take place at Polestar-authorized service centers which, in keeping with the brand’s hybrid business model, is handled by franchised dealerships even though Polestar doesn’t sell car cars through them.

Power steering could fail in over 370,000 Teslas, recall initiated

- Tesla spent over a year investigating the issue at the behest of a non-U.S. regulatory agency

- In the U.S. Tesla’s latest recall affects the 2023 Model 3 and Model Y

- Tesla’s NHTSA recall filing leaves unanswered questions for global markets

Tesla has acknowledged over 300,000 of its EVs could lose power steering.

On Thursday, Tesla’s Daniel Donovan, Technical Publications Manager, filed an acknowledgement with the National Highway Traffic Safety Administration (NHTSA) that stated the automaker will be conducting a recall. The recall, posted a day before by the agency, involved 376,241 Tesla EVs.

Specifically, the recall involved the 2023 Model 3 sedan and 2023 Model Y crossover.

Tesla estimates only 1% of the vehicles included in the recall have the defect.

Those vehicles were manufactured in the U.S. prior to software release 2023.38.4. Model 3s affected were produced between February 28, 2023 and October 11, 2023 while Model Ys were assembled between February 24, 2023 and October 11, 2023.

These vehicles are equipped with electronic power-assist steering (EPAS) systems that, prior to software version 2023.38.4, could experience a code error that leads to overstressed motor drive components. Tesla said that if this occurs above 0 mph, steering effort will not be affected though alerts will appear on the vehicle’s dash-mounted screen. Once the vehicle reaches 0 mph, the steering system will revert to a manual system without assist. It’s unclear how long and under what conditions the reversion to manual steering would persist.

Tesla acknowledged this could increase the risk of a collision. Tesla will recall all vehicles in all markets affected by this situation, but failed to mention how many vehicles that would include outside the U.S. or detail those vehicles.

Tesla said software release 2023.38.4 and beyond resolve the issue, and that as of January 23, 2025, some 99% of affected vehicles in the U.S. have installed the release or later software versions. Tesla did not mention how many vehicles outside the U.S. have been updated or any information pertaining to those vehicles. U.S. vehicles in production rolled off the assembly line with the updated software as of October 11, 2023.

The recall notice said an unidentified regulatory authority in a non-U.S. market area opened an investigation into complaints related to the loss of power steering by the described conditions. Tesla spent over a year performing technical reviews with this unidentified authority before issuing a recall for vehicles affected on January 16, 2025. The automaker didn’t file the report with the NHTSA until February.

Tesla admitted in the filing that it has identified over 3,012 warranty claims and 570 field reports in the U.S., but does not expand on any claims or reports outside the U.S. market, which is where the original investigation started. Tesla claimed it’s unaware of any crashes, injuries, or deaths related to the condition.

Tesla’s already issued a large recall in 2025 and seven Cybertruck recalls in 2024 alone. The automaker’s sales fell in 2024 while its share of the U.S. EV market fell below 50%.